Though animal testing is an essential part of vaccine R&D, Gideon Kersten, Chief Scientific Officer at Intravacc, believes its role in quality control is debatable. “Not only have our analytical capabilities improved spectacularly, but production processes are now better controlled,” he says. “It should be possible to reduce our animal use if in vitro tests can prove a vaccine is produced in a consistent manner.”

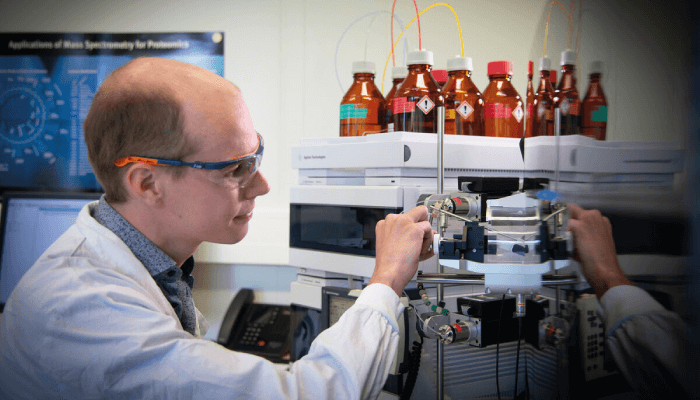

Intravacc, in collaboration with researchers from Leiden University, the Netherlands, has developed a technique that relies on the enzyme cathepsin S to establish the quality of vaccines (1). Cathepsin S can be used to measure how consistent purified native pathogens in vaccines are inactivated. “The inactivation step in the development of some vaccine types is critical and relies often on formaldehyde,” says Kersten. “Using mass spectrometry, we quantified how quickly the enzyme breaks down proteins in vaccine products. The rate of degradation was used as an indicator of how well formaldehyde inactivated the vaccines we tested.”

Though the process initially seemed straightforward, the team soon realized that it would be difficult to execute. “Using formaldehyde is really messy! The protein fragments we studied were not only inactivated, but extensively modified by the compound, and we ended up with a heterogeneous mixture,” Kersten says. “Though we mapped these modifications in great detail, we then turned our focus to quantifying the breakdown of peptides that were not modifiable because identification of unmodified peptides by mass spectrometry is easier.”

The change in direction allowed the team to accurately determine the effect of cathepsin S on degradation. “We now have a method that allows us to establish vaccine quality without animal testing,” Kersten says.

The team is now working towards validating their approach before seeking regulatory approval.

References

- TJM Michiels et al., Sci Rep, 10, 11535 (2020).