With Richard Bonocora, senior lecturer at Rensselaer Polytechnic Institute

One day, a student, Joe Adam, who had previously been in my class, came to ask if I still had the bacteria we had worked on that expressed green fluorescent protein. When I said yes, he asked if I would like to send them into space.

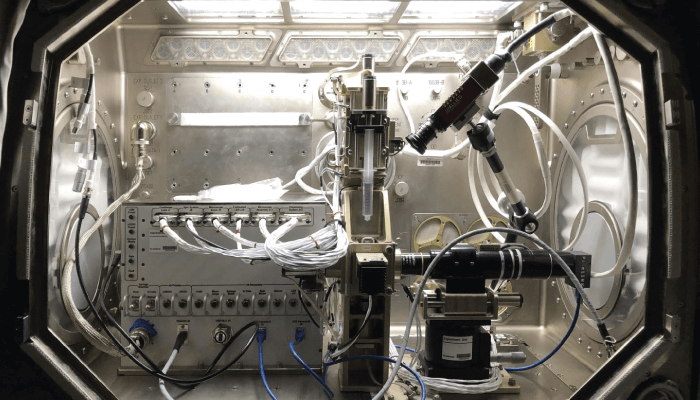

He was working on a project with Amir Hirsa, a professor of Aerospace Engineering at Rensselaer, involving the ring-sheared drop (RSD). The RSD was developed to study the flow within liquids without the constraints of solid walls, something that can only happen in the absence of gravity. In microgravity, free liquid naturally takes on a spherical shape and it is this property of liquids that the RSD exploits. The edges of two cylinders (contact rings) touch the drop and use surface tension to hold the drop in place. One ring then rotates while the other is stationary, producing flow and mixing throughout its volume through the action of surface shear viscosity– all without the need for a solid container.

On Earth, bacterial cultures are often grown in incubators and require mixing of the liquid to promote gas exchange (aeration), which is optimal for many of the organisms used as biotechnology platforms today. However, efficient mixing in current space-based bioreactors may be limited. Joe made a connection between the fluid dynamics technology that Amir was developing and the biological principles he learned in my class, and came up with the idea of using the RSD as a bioreactor to more efficiently aerate and grow microorganisms such as E.coli in space. These microorganisms could be used to help astronauts produce protein-based medicines that may be necessary during long-term space exploration. Currently, inhabited space missions are limited to low Earth orbit (LEO) on the International Space Station. Basic human necessities, including pharmaceuticals, food, and water, are provided by frequent resupply missions. The need for pharmaceutical production becomes important as the missions become more adventurous and spacecraft travel past LEO to the Moon, Mars, and beyond. I was intrigued – and thus began my interest in the field of space microbiology.

As with other bioreactors, the RSD will require a motor and a harness to secure it during space flight, but since surface tension is doing all the heavy lifting regarding the liquid, there is no additional container weight. Furthermore, problems of biofilm formation and the resulting biofouling that have been observed on previous space missions are substantially mitigated as only contact rings touch the culture.

My collaboration with the team began a few years ago. Since then, the RSD has been installed on the International Space Station (2019) and is being used to study the formation of protein clusters like those found in brain tissue in neurodegenerative diseases (1).

We recently reported on how we used a ground-based analogue of the RSD called the knife-edge surface viscometer (KEV) to evaluate the feasibility of growing microorganisms in microgravity and the RSD (2). The RSD only works in microgravity, which makes it difficult to test on Earth! However, tests with the KEV, which also uses surface shear viscosity to produce mixing, show that it is a viable method of growing E. coli. In addition, recombinant protein expression was comparable to using standard growth methods. We’re now planning to do tests to see if the RSD can successfully hold drops with living bacterial cultures during short bursts of microgravity on a parabolic flight (also known as the Vomit Comet) (3). I’m positive that we will see some good results!

I am now working on optimizing microorganisms for space, by selecting or engineering the new organism(s) for producing biologics in space with improved functions such as growth rate and protein production. At the moment, we are focusing on improving resistance to radiation. As missions extend deeper into space, exposure to galactic and solar radiation will increase. Astronauts will need adequate shielding to protect them from such exposure. Microorganisms used to produce biologics will also need shielding. However, we are interested in reducing the amount of physical shielding needed by microorganism biofactories. There are microorganisms that have extreme resistance to radiation. We are investigating how to harness these abilities and put them to use with more biotechnologically amenable species to create a “cellular shield” that protects the contents of the cell, namely the desired biologic.

In essence this will transfer the shielding burden from the spacecraft to the cellular factory and will allow more shielding mass to be devoted to the astronaut cabin. I liken this to the difference between the insulation needed in a family’s home as compared to that needed for their garage. Garages are always cold or hot, but you don’t have to live in them!

I am fortunate to be working at Rensselaer with so many bright students like Joe who have so many great ideas. I am also fortunate that Rensselaer has an extremely supportive collaborative environment. Fluid dynamics and engineering expertise lies with Amir, Joe and Shreyash Gulati (another member of our team who provided critical analysis to our KEV work). My role lies on the microbiology side. I believe collaborations like ours that combine different disciplines are what’s important to drive science forward.

References

- NASA, “NASA, Industry Partner for Space-based Study of Potential Alzheimer’s Key,” (2019). Available at https://go.nasa.gov/2I0SNPQ.

- JA Adam et al., “Growth of microorganisms in an interfacially driven space bioreactor analog,” npj Microgravity, 6 (2020).

- NASA Flight Opportunities, “Adapting the ring-sheared drop (RSD) technology as a bioreactor,” (2020). Available at https://go.nasa.gov/36Kj7YM.