As technology advances, regulators are demanding ever-greater precision, accuracy and reproducibility of assays used during pharmaceutical development. The goal is clear: to ensure that the products ultimately delivered to patients are of high quality. Bioassays are an important component in ensuring regulatory compliance, and effective bioassays require reproducible cell lines; analytical bioassay cell banks are commonly used to provide the necessary cells.

There is a large amount of guidance – both regulations and standards – governing the production of GMP production cell banks, notably the ICH document Q5D on the derivation and characterization of cell substrates used for production of biotechnological and biological products (1). These will be serially sub-cultivated cells that are characterized by common starting sources for each production lot; in other words, they are preserved banks of cells. The guidance states that the identity, purity and stability of the parental cell line, and subsequent master and working cell banks, must be confirmed.

For analytical cell banks, however, the situation is not so clear-cut. In fact, there is no real guidance on what is required. Perhaps the best current set of recommendations is contained in a 2012 paper by Menendez et al., which also states that non-GLP and non-GMP best practices should be performed and documented in a way that it is consistent with the future use of cells in analytical methods that have to comply with GLP or GMP (2).

Several factors should be considered when making an analytical cell bank. In many cases, it is appropriate to use a tiered banking strategy, with master and working analytical cell banks. The cells can be frozen in appropriate media for future use. There are numerous technologies available to control the freezing of cell banks, but the cells must also be subject to analysis performed under protocol, to check both their purity and their function. A purity analysis involves two-stage viability testing: immediately after the thaw, and again a day or so later, including tests for fungal and bacterial sterility, as well as mycoplasma testing. For assay function, at least three random vials from each master and working cell bank should be tested in the bioassay itself.

The most important advice that we can give is that you must develop a good understanding of the cells, culture reagents, and conditions, and ensure that the cell bank is appropriate to support your bioassay. As a non-GxP procedure that will support GxP analysis, a quality assurance signature may still be required on protocols and reports, with substantial documentation for every step. You also need to bear in mind that the biology of cells is variable. Naturally, any plate-based assay may show variability during development and use – variability that can be exacerbated if your cells are not reproducible. You’ll also require proper procedures and documentation to ensure that the characteristics of the cells themselves are known.

Putting cells to the test

The history behind your cells and cultures can significantly affect the phenotype of the cells, and therefore their morphology and response. Because of this, it is important to maintain a full history of your cells to ensure their provenance, including the tissue type, method of isolation and type of cell. There should also be good documentation of the passage or population doubling history, the media that have been used for culture, and any prior results from cell identity and biological quality tests.

ICH Q5D for production cells states that appropriate tests should be performed to determine that the banked cell is what it is claimed to be, including its phenotypic and genotypic characteristics. It is not necessary to carry out every single possible test, but several should certainly be done to guarantee that the cell is what you think it is.

Examining the cells’ form and structure with photomicroscopy is one test that can be performed, but it can be tricky, and is usually only viable with adherent cells. Moreover, despite its frequent use, it is not generally accepted as proof of identity as the same cell can look different depending on how it was cultured. Nevertheless, photomicroscopy is still useful for training, cell culture maintenance and record-keeping.

Genotyping is another required test defined by ICH Q5D. For this type of testing, full DNA sequencing is the most foolproof method, but it is expensive and time-consuming, and so is not always practical. Faster surrogate techniques can be considered; banding cytogenetics or DNA analysis (either using gels or qPCR) can detect a genomic polymorphism pattern. Such “fingerprinting” can provide confirmation of species of origin and known unique cell line markers – and is definitely considered an adequate test of identity. To be clear, such level of detail is not explicitly required for an analytical cell bank. However, if available, it is a characterization test that can provide important supporting data for the use of that cell line.

For an analytical cell bank, although it is good practice to confirm the cells’ identity, it is far more important to know whether the cells will respond to the therapeutic being tested in a predictable fashion. Information about cell line stability is essential, including the number of times the cells can be doubled before the functional response begins to shift significantly. It is possible for a non-pure population of cells, or an unstable genotype, to outgrow the desired cells, which will result in loss of functionality of the cell bank.

Similarly, for phenotypic identity, a combination of methods should be considered, including microscopy. Protein secretion analysis, either via ELISA or protein arrays, is more exacting, and flow cytometry or electrochemical luminescence (ECL) can be used to study cell surface protein expression. At the molecular level, reverse transcription-qPCR or microarrays can be effective for examining mRNA expression. You should also consider biologic functionality when looking at phenotype, and how this changes in response to the therapeutic – death, apoptosis, proliferation, or a change in the proteins that are secreted or expressed on the cell surface. Also, consider how this changes over multiple population doublings.

It is also important to consider how the cells will be used in the assay. For cells that are maintained in a continuous culture, the cells must remain in optimal condition on every culture passage. Cells should not be subcultured based on a volumetric ratio; rather, this should be done based on numbers of cells per milliliter or square centimeter. The cells must be in log-phase growth at all times, and every stress condition, such as over- or under-growth or nutrient deprivation, has the potential to cause a change in their behavior. In fact, continuous culture is a common source of variation in bioassays.

An alternative strategy is to use a technique such as “thaw and go”. Cells are frozen from culture, with a per-vial density sufficient for more than the 96 wells on a microtiter plate. The cells are used immediately, or within 24 hours, being placed directly into the assay once they have thawed. The cells should be as healthy as possible before they are frozen, although it may be necessary to filter out cell culture aggregates. This strategy significantly reduces the potential for stressed culture condition, because the cells simply become a critical reagent once they have been qualified.

Banking on bioassays

R&D banks save time by allowing assay optimization, and even some prevalidation, while the GMP bank(s) is/are being generated and validated – a real benefit. And if the banks are protocol-documented, they can provide supporting scientific data for future GMP production activities.

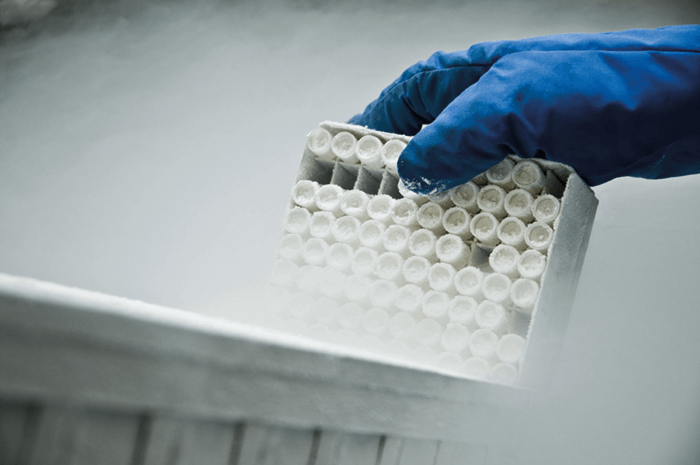

To create a bank, you can use multiple 175 cm2 culture flasks for both adherent and non-adherent cell lines. Cells can be harvested using 50 mL polypropylene centrifuge tubes, and then pooled into a single centrifuge tube, washed several times, before being quantified using trypan blue viability tests. The next step is to re-suspend the cell pellet in an appropriate volume of chilled cryopreservation medium, which is then split into 1 mL aliquots in separate cryovials. These are then frozen using liquid nitrogen in a controlled rate freezer. Such a manual technique is practical for up to about 100-150 vials, but you need to take care when it comes to maintaining homogeneity of the vials, as the cells will settle while they are being aliquoted.

It takes around 21 weeks to prepare a cell bank: five weeks for preliminary testing, three weeks to produce and a further five weeks to characterize the master cell bank. A similar eight-week timespan accounts for the production and characterization of the working cell banks, and then the vials should go into secure long-term storage, which of course should meet GMP conditions.

- Generating smaller sized GMP analytical cell banks (especially working analytical cell banks, or WACBs) may be tempting if resources are limited. The trade-off is the high likelihood that “absolute” assay responses may shift significantly between banks as a result of a combination of different culture passage numbers and potentially different culture conditions. While generated relative potency values, by definition, ought not to be impacted, curve dynamics, and thus data analyses, may well be impacted.

Response: It is well worth doing whatever is required to resource for making as large a bank as may be needed for at least a 3 to 5 year period. This is especially true for thaw and go WACB.

- Aliquoted cells may not survive the freezing process. This may manifest in several ways. The most drastic is that the cells are completely nonviable upon thawing. More subtle, but no less impactful, effects may be that the cells are overly stressed (with lowered viability) upon thawing, but can recover in culture. While apparently fine, these cells may no longer respond to ligand in the way that they did prior to freeze. If the cells are intended for thaw and go use, then there would not even be the possibility of in-culture recovery.

Response: To begin with, it is important to test and identify the best freezing media for your particular cell type. Secondly, if at all possible, use a controlled-rate (step) freezer, either LN2-based or mechanical-based. While the “Mr. Frosty” type -80C freezer containers do work reasonably well and are able to achieve a slowed rate of freezing, they are not actually controlled. A controlled-rate freezer is designed to customize and differentiate the rate of temperature drop for prior, during and after the freeze transition phase. Viability is significantly more assured using the controlled-rate systems.

- Cells may be stable for either growth or response characteristics for only a limited number of generations/passages. This may be due in part, for continuous culture cells, to a non-pure cell line, so that a non-responding subpopulation outgrows the responding population. For engineered responder cells, it could be due to a DNA construct that is either directly unstable or is somewhat deleterious to cell health and is selected against during normal in-culture genetic drift. For primary-cell-based assays (e.g., HUVEC) the cell may inherently only be capable of a very limited number of divisions before they senesce, unable to maintain their necessary phenotype.

Response: This is one of the many benefits of developing and utilizing a thaw and go WACB strategy. Following a very limited number of cell divisions, the bank is then set. This means that the cells may then be used for the lifetime of that bank with no more (or one to two more,, depending on cell/assay requirements) cell divisions.

Your cryopreserved banks should, ideally, be stored in two geographically separate locations or, if this is not possible, in two separate locations within the same facility. If the cells must be shipped, they should be split into at least two shipments, with temperature monitors to ensure they do not thaw. If something happens to one shipment, then at least the entire bank is not lost!

The number of frozen cells required depends on the type of cell bank. If it is a continuous culture bank, a master bank will be made up of about 50 vials, while the working cell bank will contain about 100 vials. Assuming one vial is thawed every two months, each working cell bank will contain enough cells for about 16 years of bioassays. The numbers are slightly different for a thaw and go culture bank. Again, about 50 vials will be made for the master cell bank, but at least 400 vials will be generated for the working cell bank. At a usage rate of four plates per week, this will provide sufficient cells for about two years.

The big challenge here is securing sufficient biomass to fill 400 vials! Using cell cubes, stacks or towers rather than standard flasks is more space efficient, but there are some newer technologies that can make the process easier; I recommend wavebag-type technologies (e.g, the Xuri W25; GE Healthcare), which are designed for non-adherent cells, but can support adherent cells using such strategies as microbeads.

Bioassays are a fact of life for the testing and release of biologics. Analytical cells, in turn, are a fact of life for bioassays. Thus, relative potency data for CMC testing and release, and the bioassays from which these results are derived, depend on the availability of dependable analytical cells. Stable and predictable cells are essential for running accurate and reproducible bioassays – and a well-planned, executed and validated analytical cell bank can save you a lot of time, while meeting regulatory requirements for bioassays.

Mike Merges is Director of Strategic Growth of Biologics Analytical Services, and Mike Sadick is Principal Scientist, Biologics Analytical Services, both at Catalent.

References

- ICH Harmonized Tripartite Guideline, “Derivation and Characterization of Cell Substrates used for Production of Biotechnological/Biological Products Q5D” (1997). Available at https://bit.ly/2zSxjQD. Accessed October 15, 2018. A Menendez et al., “Recommendations for Cell Banks Used in GXP Assays: Preparation, Characterization, and Storage,” BioProcess Int., 10, 26-40 (2012).