Introduction

Monoclonal antibody development projects exist for a wide variety clinical indications (1,2). Recombinant proteins of commercial interest, including monoclonal antibodies, need additional properties beyond their biological activity to enable their development into successful biopharmaceuticals. Particularly, they need to be resistant to chemical degradation and be physically stable in a given environment, without any tendency to aggregate (3,4). Furthermore, they need a favorable serum half-life and should exhibit no, or very little, immunogenic potential (5). Apart from being more expensive to produce than liquid formulations, a lyophilized drug product (DP) must be reconstituted by the physician, taking up to 10 to 20 minutes before parenteral administration to the patient. The main driving force pushing the biopharmaceutical industry to focus resources on developing liquid formulations instead of conventional lyophilized DPs is simplified administration. However, there are some technical issues to be overcome with regard to liquid formulations. The main challenge is to keep the protein biopharmaceutical stable in a liquid formulation by maximizing the physical stability and minimizing chemical degradation. It is especially challenging to develop biopharmaceuticals for subcutaneous administration because here the liquid formulation should have as high concentration of protein as possible to compensate for the limitations imposed by possible injection volume, 1.0 to 1.5 ml (6).

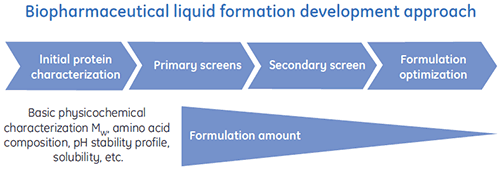

Figure 1: The liquid formulation development process This places huge pressures on the formulation development teams to deliver finely-tuned liquid formulations that optimally suit each biopharmaceutical. Structure and stability analysis of recombinant proteins, in particular monoclonal antibodies, is of considerable importance and is an indispensable prerequisite for the development of formulations for biopharmaceuticals. A variety of techniques have evolved which can be used to gain structural information and information on protein stability. DSC has become one of the key physicochemical methods to study the stability of protein biopharmaceuticals (7-11). DSC enables the rapid study of protein unfolding without labeling or the use of artificial probes, The technique determines the heat absorbed by the sample as a protein unfolds, giving a measure of its thermostability and an indication of its long-term stability. Special liquid formulation development programs have been designed to efficiently deliver optimized liquid formulations for biopharmaceuticals. A general scheme of a typical liquid formulation development process is shown in Figure 1. DSC has proved to be especially valuable in the early phases of liquid formulation development, a point at which it is preferable to rapidly reduce the number of formulations attempted both to save Drug Substance (DS) and time spent on complex analytics.

Materials and methods

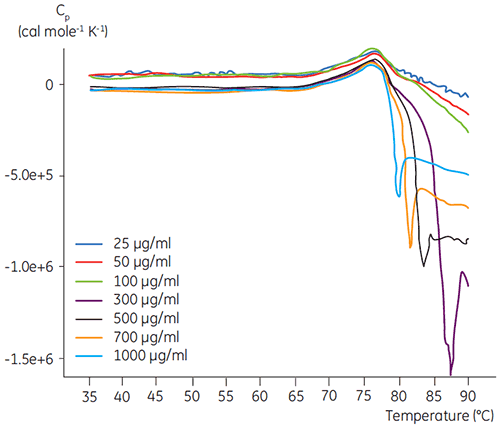

DSC experiments were performed using the Malvern MicroCal VP-DSC (Malvern Instruments) with a scan rate of 1.5 K/min. Samples were degassed for five minutes before analysis. In all experiments, the reference cell of the calorimeter was filled with a buffer corresponding to the sample buffer. Buffer baselines were subtracted from the protein scans and the molar heat capacity was used in the data analysis. The temperature-induced unfolding of all proteins was checked for reversibility by comparing the heating and reheating DSC scans (data not shown). No reversibility was found. The unfolding temperatures were acquired by analyzing the calorimetric profiles according to a two-state transition model. The optimal signal to noise ratio was found when using an antibody concentration of 100 µg/ml (Figure 2). Although higher concentrations did not impact the unfolding temperature, they induced strong exothermic heat due to the aggregation of the protein after unfolding.

Figure 2: Unfolding transitions of antibody 1 (IgG1) at different concentrations

DSC in the initial protein characterization phase

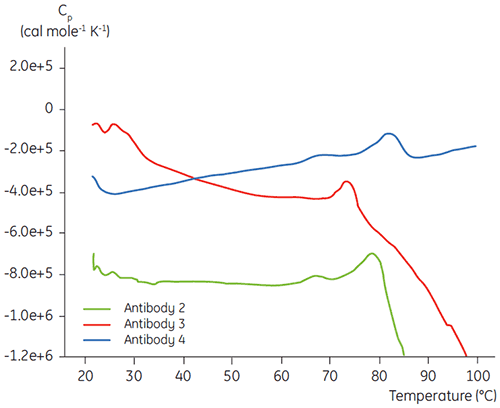

In the initial protein characterization phase of a specific antibody liquid formulation development program, DSC is used for comparing the overall stability of the antibody to other antibodies in development. As can be seen in Figure 3, large differences can be found in unfolding temperatures between different antibodies.

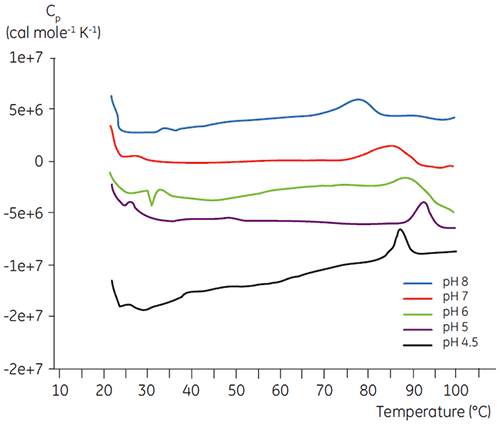

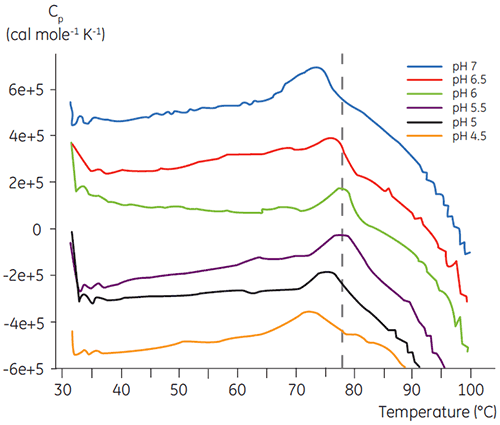

Figure 3: Unfolding transitions of antibody 2 (IgG4, 200 µg/ml), antibody 3 (IgG1, 100 µg/ml), antibody 4 (IgG1, 100 µg/ml) Like most proteins, biopharmaceuticals are very sensitive to pH and it is essential to find the optimal pH to maximize stability. DSC has proved to be an efficient tool for optimizing the pH since information can be gained without performing two and four weeks accelerated stability studies. Although most antibodies typically show the highest stability between pH 5.5 to 6 it is still important to characterize the optimal pH because deviations have been found. Figures 4 and 5 presents the pH profiles of a fusion protein and antibody 2. As can be seen, the optimal pH for the fusion protein (Figure 4) was pH 5 giving a Tm value of 92.8°C. The fusion protein was sequentially destabilized at pH values above pH 5 but was especially sensitive to low pH values. At pH 4, no unfolding could be observed (data not shown). Figure 5 shows a typical pH profile of an antibody. The highest stability was acquired at pH 5.5 and pH 6, giving a Tm value of 78.5°C.

Figure 4: The pH profile of a fusion protein (100 µg/ml)

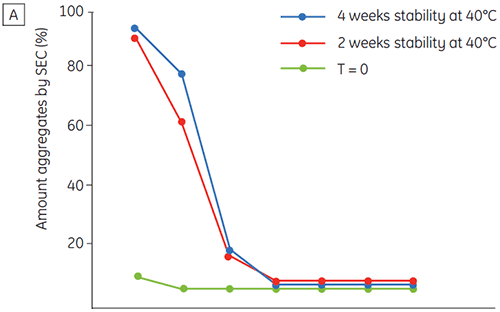

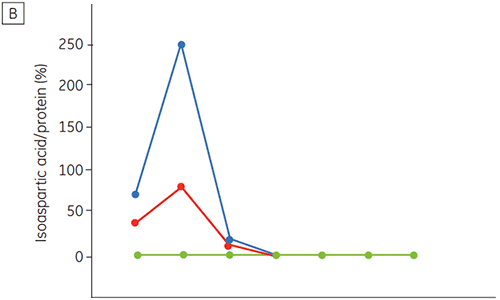

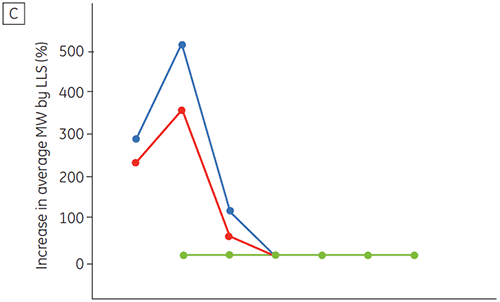

Figure 5: The pH profile of antibody 2 (100 µg/ml) Figure 6 presents data on the chemical and physical stability of antibody 2 as a function of time and pH (initial protein characterization phase). The pH stability profile study shows that after incubating antibody 2 for two and four weeks at ≤pH 5 and at 40°C marked changes in the stability occur. DSC could distinguish the optimal pH condition for this monoclonal antibody by only using the freshly prepared samples (time zero), giving similar results as the other methods (Figure 5). Furthermore, the DSC identified the ≥pH 6.5 values as destabilizing, something that was not obvious in the two and four weeks timeframe but would rather have needed an eight to twelve weeks stability study to be elucidated. In other words the DSC results correspond very nicely with the other methods that were used in this study to optimize the pH of the formulation buffer.

Figure 6: The impact of pH on the stability of antibody 2 as studied by (A) size exclusion chromatography SEC, (aggregation), (B) formation of isoaspartate, (C) laser light scattering (increase in average molecular size) (D) and DSC (Tm). The isoaspartate value is calculated according to the increase in the amount of isoaspartate/protein (mol isoaspartate/mol protein × 100) The benefit of DSC is that only the time zero samples need to be analyzed to indicate stability. This is because heating the protein is in itself stress inducing. Typically, if the native conformation of a protein is stabilized it can resist thermal stress to a higher degree (unfolds at a higher temperature) than can a protein that is destabilized. Hence, using DSC, it was not necessary to test samples on long term stability at various temperatures simply in order to acquire information about the impact of a specific liquid formulation on protein stability.

DSC in liquid formulation development (primary screen)

DSC was used in the primary screen of antibody 2 together with other biophysical methods including, SEC, laser light scattering (LLS), capillary electrophoresis (CE), and SDSPAGE, to select the most promising liquid formulations. The samples were put on an accelerated stability study and analysed after four weeks. DSC was found to be especially successful at identifying formulations that had a negative impact on antibody 2, but the technique could also identify good liquid formulations. By analyzing the time zero samples, DSC identified all four liquid formulations (formulation 2, 6, 8 and 11) in the primary screen that were deemed unsatisfactory according to the other analytical techniques. Figure 7 presents thermograms and Figure 8 presents the unfolding temperatures (Tm) of antibody 2 in liquid formulations F1 to F12 from the primary screen. The unfolding of antibody 2 in formulation F9 gave a markedly deviating unfolding pattern. For this reason it was regarded as a critical formulation.

Figure 7: Thermograms from analysis of antibody 2 in twelve different formulations

Figure 8: Tm values of antibody 2 (100 µg/ml) from the primary screen. The grey arrows indicate which formulations were regarded as unsatisfactory according to the other analytical techniques used in this study

Conclusions

DSC is a technology that is valuable in the early phases of protein characterization and formulation development. Critical data about protein stability can be rapidly acquired and used as a guide to support and speed up liquid formulation development projects.

Acknowledgement

This application note was authored by Dr Fredrik Ollila, Novartis Pharma AG.

Malvern Instruments provides the materials and biophysical characterization technology and expertise that enable scientists and engineers to understand and control the properties of dispersed systems. These systems range from proteins and polymers in solution, particle and nanoparticle suspensions and emulsions, through to sprays and aerosols, industrial bulk powders and high concentration slurries. Used at all stages of research, development and manufacturing, Malvern’s materials characterization instruments provide critical information that helps accelerate research and product development, enhance and maintain product quality and optimize process efficiency. Our products reflect Malvern’s drive to exploit the latest technological innovations and our commitment to maximizing the potential of established techniques. They are used by both industry and academia, in sectors ranging from pharmaceuticals and biopharmaceuticals to bulk chemicals, cement, plastics and polymers, energy and the environment. Malvern systems are used to measure particle size, particle shape, zeta potential, protein charge, molecular weight, mass, size and conformation, rheological properties and for chemical identification, advancing the understanding of dispersed systems across many different industries and applications. Headquartered in Malvern, UK, Malvern Instruments has subsidiary organizations in all major European markets, North America, Mexico, China, Japan and Korea, a joint venture in India, a global distributor network and applications laboratories around the world. www.malvern.com severine.michel@malvern.com

References

- Chester, K. et al. Engineering antibodies for clinical applications in cancer. Tumour Biol. 25, 91–98 (2004).

- Harris, M. Monoclonal antibodies as therapeutic agents for cancer. Lancet Oncol. 5, 292–302 (2004).

- Parkins, P. A . and Lashmar, U.T. The formulation of biopharmaceutical products. PSTT 3, 4 (2000).

- Wang, W. Instability, stabilization, and formulation of liquid protein pharmaceuticals. Int . J. Pharm. 185, 129–188 (1999).

- Schellekens, H. Immunogenicity of therapeutic proteins: Clinical implications and future prospects. Clin. Ther. 11, 1720–1740 (2002).

- Shire, S.J. et al. Challenges in the development of high protein concentration formulations. J.Pharm. Sci. 93, 1390–1402 (2004).

- Vermeer, A.W. et al. The unfolding/denaturation of immunogammaglobulin of isotype 2b and its F(ab) and F(c) fragments. Biophys . J. 79, 2150–2154 (2000).

- Vermeer, A.W. and Norde, W. The thermal stability of immunoglobulin: unfolding and aggregation of a multi-domain protein. Biophys . J. 78, 394–404 (2000).

- Welfle, K. et al. H. Conformation, pH-induced conformational changes, and thermal unfolding of anti-p24 (HIV-1) monoclonal antibody CB4-1 and its Fab and Fc fragments. Biochim. Biophys . Acta 1431, 20–31 (1999).

- Remmele, R.L . Jr et al. Interleukin-1 receptor (IL-1R) liquid formulation development using differential scanning calorimetry. Pharm. Res .15, 200–208 (1998).

- Matsuura, J.E. et al. Biophysical characterization of a soluble CD40 ligand (CD154) coiled-coil trimer: evidence of a reversible acid-denatured molten globule. Arch. Biochem. Biophys. 392, 208–18 (2001).