The goal of granulation is to take fine, non-compactable powders and turn them into coarser agglomerates that can be pressed into tablets. Agglomerates can be composed of dry, solid granules, where each granule represents an agglomerate of primary particles with sufficient solidity. In the dry granulation process, agglomerates are created through mechanical pressure alone.

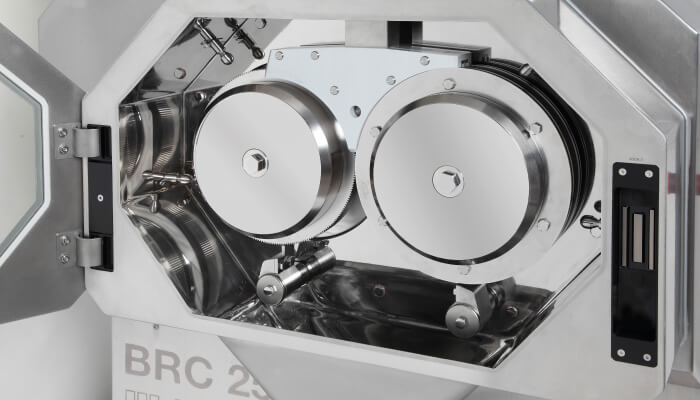

With our BRC series, powders are processed to free-flowing granules with a defined density or porosity that allows for immediate pelletizing after compacting. We wanted to offer better performance than the existing products on the market so we designed the BRC to offer a high level of product capacity with minimum material loss. Force is generated by purely electromechanical means to ensure consistent ribbon properties and it can evenly compact material over a production range of 1-400 kg/h (product dependent).

The powder is compacted between two rollers with specified gap widths. The impact on the rollers, as well as the gap width, is monitored via sensors and there is also the option to install process analytical technology (PAT). All data are integrated into a control circuit to ensure continuous process quality, while an electro-mechanical drive provides precise and fast control. The chopper unit below the compacting rollers processes flakes into a granule at a defined granular size, and the unit is equipped with a conical sieve with replaceable inserts for different particle sizes. Even at high material throughputs, the cone-shaped sieve and its inserts gently crush the ribbons into granules with the desired particle size distribution. Each BRC can be mounted with a different rotary sieve within minutes to adjust to new process and ribbon requirements.

During the development of the series, engineers paid particular attention to make scale-up from the BRC 25 to BRC 100 as easy as possible by using identical roller geometry and control in both machines.

Of course, ease-of-use, targeted control, cleaning and hygienic design were all considered; when developing equipment for the pharma market, getting these aspects right is essential!

When developing systems and equipment, I think it is important to ensure they are robustly manufactured and can be used for many years. Some Bohle products have been used in production for over 20 years and in several shifts daily! The BRC requires extremely low maintenance as hydraulic technology was abandoned entirely. Cleaning and inspection are essential to ensure long-term reliability, and we also advise a regular service.

Roller compaction, or dry granulation, is receiving a lot of attention from pharma manufacturers because roller compaction is a continuous process by design – and many companies are considering a move to continuous manufacturing. Dry granulation is an established procedure for producing pharmaceutical solids. It is employed not only for products that are sensitive to moisture or temperature, but also for its cost advantages. In comparison to wet granulation, no energy-intensive drying processes are necessary. Without a drying step, it becomes superfluous to stock up on, distill and dispose of industrial solvents.

Today, a wide range of different granulation systems are available on the market. Wet granulation systems are divided into fluid bed granulation, high-shear granulation, single-pot granulation and twin-screw granulation. The units for dry granulation/roller compaction can be classified by roll assembly and layouts, sealing systems and roll surface conditions. Dry granulators are differentiated on the basis of their roller configuration; there are granulators with rollers configured horizontally, vertically and diagonally. We’ve seen a lot of demand for horizontally-configured rollers; advantages of this configuration include improved de-aeration of the screws and a shorter discharge route for the slugs. In addition, dry granulators vary in terms of the width, diameter and surface characteristics of the rollers.

The system you choose will depend on the needs of your API and your business. I advise considering:

- Product capacity, capacity for each batch, and throughput

- Process robustness

- Scale up

- Process and product understanding

- Flexibility (including batch sizes, integration of different set up processes and the ability to react to market demands)

- Service and maintenance costs and requirements

- Footprint of the unit and requirements for the GMP area

Continuous manufacturing processes will determine the future of the pharmaceutical industry. Changing frameworks in the healthcare systems of the large pharma markets, such as the US and Western Europe, have been accompanied by budget reductions and economization processes in recent years – with many manufacturers changing their mindsets in terms of how they produce medicinal products. Today, there is a huge emphasis on the cost of drugs.

Continuous processing has great potential for more efficient and cost-effective manufacturing of tablets and meeting regulators’ – specifically the FDA’s – calls for improved safety and product quality (the FDA has also been vocal about PAT and continuous manufacturing).

For L.B. Bohle, continuous production is shaping the future of pharmaceutical solid dosage production machines.

Another system offered by L.B. Bohle for continuous processing is QbCon, a modular processing line that produces coated tablets out of raw powders within a single production stream. QbCon is produced in partnership with Korsch (tablet presses) and Gericke (continuous feeding and blending). allows the flexible arrangement of different unit operations, depending on the requirements of the customer. Several routes of manufacturing tablets from powders are feasible in the setup; for example, continuous direct compression for suitable powder mixtures or continuous wet granulation to improve the bulk properties of the powder before tableting can be conducted. The line also includes roll-compaction/dry granulation in a continuously working process, which is much more economic and less energy intensive than a wet granulation process.