In 2014, our sister publication – The Analytical Scientist – launched the Humanity in Science Award in collaboration with Phenomenex. The goal? To identify a breakthrough in analytical science that has truly benefited humanity. Now, the winning project has been revealed: a new, cost-effective production method for antimalarials, developed by Peter H. Seeberger and Andreas Seidel-Morgenstern of the Max-Planck Institutes in Potsdam and Magdeburg, respectively. By coupling flow chemistry with advanced chromatography methods, Seeberger and Seidel-Morgenstern were able to manufacture artemisinin combination therapies (ACTs – the most effective drugs to treat malaria) from plant waste material, air and light. The new process is currently being implemented in a pilot plant in Vietnam and produces an active pharmaceutical ingredient with a purity of greater than 99.5 percent.

Artemisinin was discovered in the 1970’s as a promising antimalarial candidate; unfortunately, its molecular complexity has pretty much thwarted attempts at commercial synthesis. Instead, artemisinin is almost exclusively obtained via extraction from the wormwood plant, which is mainly grown in Vietnam. An unstable supply creates a volatile market and, worse still, up to 50 percent of ACTs in Africa and Asia are counterfeit.

“This recognition of our work by an international jury of leading scientists encourages me to continue our work on translating our scientific breakthrough into a production facility. Thereby, those in need of malaria medications will benefit from better access and lower prices, while the dangers of fake medications are reduced,” said Seeberger, who is director of the Institute of Colloids and Interfaces. “This process is just one example of the power of continuous processes that will revolutionize the production of life-saving medications in developing countries.” Seidel-Morgenstern, director of the Department of Physical and Chemical Foundation of Process Engineering, continued, “An efficient isolation of a continuously synthesized target component requires the development of advanced separation processes. Considering the reactor effluents generated in Peter’s group as pseudo-ternary mixtures (an impurity fraction 1, the target, and an impurity fraction 2), artemisinin and artesunate could be purified with our process using several periodically operated chromatographic columns. The approach can be applied to also solve other challenging separation problems.”

Editor of the Analytical Scientist, Rich Whitworth commented, “Though the chemistry and engineering involved in this project are both spectacular and innovative, the impact of the resulting complete process is most spell-binding. Peter highlighted in his acceptance speech that 660,000 people die of malaria each year – and 90 percent of those are children under five. Sadly, it is a disease of poverty – the question is, how can we stand by and do nothing? Peter and Andreas have proven that collaboration and perseverance can provide the ultimate reward – and they are already applying their production philosophy to other global diseases.”

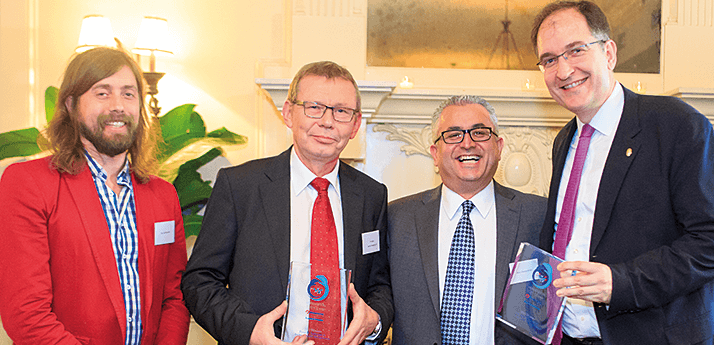

Seeberger and Seidel-Morgenstern presented their work at two symposia held at the Pittcon trade show in New Orleans, and received $25,000 in prize money at a gala dinner. We’ll be sharing the story behind their work in a future issue of The Medicine Maker. To read more about the winners and runners up, and to keep updated on the 2016 award, visit www.humanityinscienceaward.com.